CXSW three networks belt filter press to my introduction, digestion and absorption of advanced technology of Finland, to develop and produce the latest generation of patented dewatering equipment, processing capacity, high dewatering efficiency (from the slurry into the concentration of 0.8-3% can be directly increased to 28 more than -35%), lower energy consumption, it is not only to solve the traditional ordinary dual-network filter press dewatering of raw materials appear to run material, but also solve the problem of small network at both ends of material pressure, as the latest The models are pre-to dehydration network case, the natural gravity of the sludge dewatering area lengthened, but the Internet is not squeezed, the mesh can not easily be fiber, sludge clogging. Compared to more traditional filter press: the amount of net and amide reduced by 10-30%, and the structure is simple, easy to install a sludge filter press, the extraction of black liquor or slurry concentrate the ideal product.

Second, the structural features:

The three networks filter press consists of a number of different diameter roller installed in the bracket on the mixing tank composition, driven by the drive roller (middle, lower) network, dewatering roller, tensioner roller, guide roller, corrective devices and dewatering roll both ends of the sealing device. Filter using compressed air pressure up tight, so the entire network with to maintain a constant tension, not into the feeding amount of the changes caused by changes in tension; the aircraft is also equipped with a pneumatic offset compensator, and more convenient to operate and manage, more for new and practical features at both ends of the at least one or more of the dewatering roll with seals, the seals from the seal with wheel drive sealed with sealing pressure to set the horizontal at both ends of the Internet and network overlap and between the rollers with an up tight roll. With the dehydration of the rotation of the roller, to bring the sealing tape and the roller follower rotation, slurry, nets in addition by the dehydration of a roller compression, but also by the extrusion of sealing tape, and thus play strengthen the purpose of dehydration and slurry seal.

Third, it works:

Based on the difference of the dehydration zone pressure, the entire dehydration process of the wire part can be divided into pre-dehydration zone, pressure dewatering zone and pressure forced dehydration District.

Slurry cloth pulp evenly distributed on the Internet pre-dehydration zone, into the gravity dehydration. Sludge in the region by its own gravity to take off most of the water slurry loss of mobility, dehydration concentration raised to 3-5%. Then continue in the online face dehydration, the slurry into the Central, the net formation of wedge-shaped intersection area, the pressure dehydration. Slurry in the region by the next filter's mild extrusion, dehydration to 15-20%, and then into the pressure dewatering zone. Pressure dewatering area on both sides of the filter by the dehydration of eight different diameter roller rapid dehydration in the extrusion process. Dehydration pressure roller diameter gradually small arrangement and the change of filter corners, to ensure the formation of dehydration increasing pressure and the corresponding shear force, so that the pulp repeatedly in the "S" shape dehydration District deformation and off constantly In addition to the water concentration of 28-35%, the formation of mud cake, and finally scraped off by the scraper. Shed a slurry of the filter into the next work cycle after the high-pressure water wash clean.

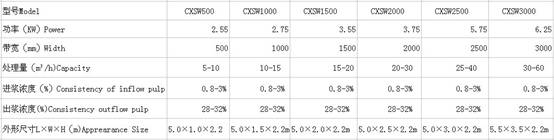

Fourth, the technical parameters:

A. Foundation drawing pouring the concrete foundation, as required to set aside the bolt hole, the surface of the base should be reserved for 20-30mm secondary grouting layer.

Two. The equipment should be based on the pool situation and the weather conditions by 10-30 days of conservation solidified before equipment installation.

3. Lifting equipment, the stress points should be located on both sides of the rack, and can not be the point of load placed on any roller or other non-lifting parts.

4. Foundation bolts in the bolt holes on the base of the device, and then hanging the device on the basis of the foundation bolts located around the foot screw resides Kong, baseline alignment leveling, check the mounting dimensions.

5 Pad into the wedge between the foundation and equipment base, the formation of 20-30mm the second filling layer, the adjustment of the wedge, the filter press at the horizontal level of 0.2mm / m, and then gravitropism feet reside hole grouting.

6. The first grouting conservation 7-15 days later, the device accurate to find the positive leveling, locking bolt, the second grouting, clean surface, the conservation of 10-30 days, you can follow the rules.

VI Operation:

A. Check and tighten the screws of the fastening parts.

Two. Check into the hopper, dewatering roller, guide network roll, and other parts of the horizontal, vertical, parallel situation.

3. Cord, respectively, along the running route, under the filter with bypass check the operation of the barrier-free.

4. Check the lubrication part of the closing ceremony of re-oiling.

5 Connected to electrical wiring and other piping, check the motor rotation status.

6. Adjust the spray angle of the flushing water mains, water pressure.

7. Check the filter with the correction, up tight on both sides of synchronization state.

8. Check all pneumatic components of the flexible movement.

9. Take a good running route along the filter with filter belt.

10. Thoroughly washed up and down the filter belt and related piping.

11. Start the air compressor, When the barometric pressure normal, adjust the filter belt tension and open the rinse water.

12. Power supply connected to the host, slowly increase the motor speed while observing the mechanical operation, ensure that no unusual circumstances, and then increase the speed to normal operating speed.

13. Normal operation of the machine, open the feed valve, while observing the discharge, control of material thickness 15-20mm, the concentration of the material in more than 28%.

14. Shutdown to close the slurry gate to stop the feed.

15. Machines continue to operate to the filter with a rinse, turn off the main motor.

16. Turn off the air compressor, turn off the rinse water.

Seven maintenance:

A. Often to check the equipment, pay attention to the connection of various parts are tightened, the bearing of the rotating parts with or without overheating.

Two. Machine lubrication points for each rotation of both ends of the roller bearing lubrication cycle for five days, grease lubricant for the 2nd.

3. The device should be installed in the indoor.

4. Recommended that the equipment once every three months to repair, overhaul once a year, according to the usage of the machine, development of maintenance plans.

Eight, after-sales service:

Where to buy I plant my plants are free to guide the installation, commissioning, perennial preferential supply accessories, and professional and technical personnel to provide technical services.