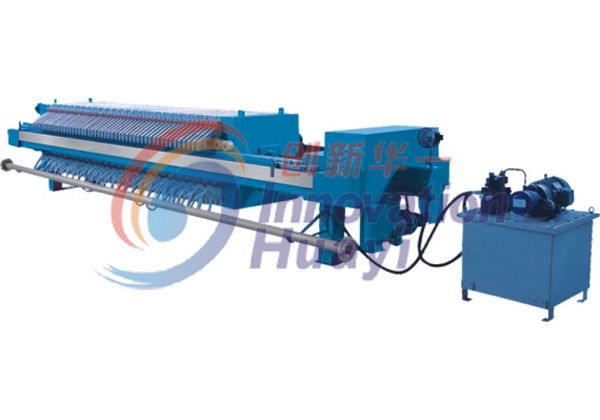

CXBY series plate filter press is an intermittent solid-liquid separation equipment, the arrangement constitutes the filter chamber, filter plate, filter box and pump pressure, the raw material sent to each filter chamber through the filter media, solid and liquid separation. Widely used in chemicals, dyes, oil, ceramics, pharmaceuticals, sugar, food starch, metallurgy and other industries of sewage treatment. It has good separation efficiency for a wide range, easy operation, low investment, etc., especially the separation of the stick thin materials have different incomparable superiority.

Plate filter press with motor parts are used OCr19Ni9 quality resistance to corrosion of stainless steel material, applicable to filter a variety of pH value of acid and alkaline solutions, the machine should be pressure sealed filter, the filter less wear and tear; filter of good quality and high efficiency. Filter in part by the nine filter plate, filter area, and large liquidity; and can be filtered solution of different production processes (initial filter, semi-fine filter, fine filter) requirements, replacement of different membranes, and production flow based on user the size may be appropriate to reduce or enhance the filter plate layers, making it suitable for production needs, this machine has a machine for a wide range of features; filter plate plane threaded mesh shape, advanced structure, no distortion, easy to clean, can growth of the service life of various membrane, thereby reducing the production cost savings, this unit is equipped with stainless steel infusion pumps, equipped with a motor small, low power consumption. The base is equipped with rubber tires, easy to operate mobile and flexible, available for mobile use.

Second, the characteristics

(1) under the same operating conditions (such as infusion pumps, power and working time, etc.). The plate filter press can make use of a mechanical force, narrowing the cavity volume of the filter plate, extrusion residues in water, make it moisture to further reduce.

(2) of the filter of any brand at home and abroad, its residues moisture content with the work hours of infusion pumps decreases. By the working hours of the infusion pump - Residue moisture characteristic curve indicated that the infusion pump working hours - Residue moisture characteristic curves are very similar. Infusion pump to work three hours before residues decline of the moisture content is very obvious from the initial 99% to about 82% (a decrease of 17%), after infusion pumps no longer work for about 5 hours, the water content rate to fall to around 75% (decrease of only 7%). Plate filter press take full advantage of the working hours of the infusion pumps - characteristics of the residues moisture characteristic curve and work three hours after stopped its work in the infusion pump shed rigid pad, external P3 residues in part of the water squeeze out, so that residues of moisture can be quickly reduced to about 75%, greatly shorten the dregs out of the time of the filter plate - filter box, and improve work efficiency. Therefore, the plate pressure filter is an energy efficient environmentally friendly products.

Third, the first step compression

The filter press operation required the machine to check: view the cloth with or without discount or overlap, the power supply is properly connected. Can check the compression operation, first press the "start" button, the pump started working, and then click the "pressed" button, piston driven compaction plate compaction, when the pressing force to reach it is set high point pressure hydraulic system automatically jump stop.

4, the second step feed

When the filter press pressed, you can feed operation: open the feed pump and slowly open the valve of the feed and the feed pressure is gradually increased to normal pressure. Then observe the leakage between the filter fluid and filter plate filter press out the liquid orifice fluid volume in the filter after a period of gradually reduced, then filter indoor Residue is gradually filled, not the mouth when the liquid solution or only a small amount of liquid that filter indoor residues has been completely filled to form a filter cake. If you need into the washing on the cake, or dried, can be followed by such does not require washing or drying operation can be carried out for cake discharge operations.

Fifth, the third step of washing or drying

Filter press cake is full of shutting down the feed pump and the feed valve. Opened the washing pump or air compressor, slowly open into the lotion or the air intake valve and the filter cake washed or dried. Operation is complete, close the lotion pump or air compressor valves, cake discharge operations can be carried out. Fourth step cake discharge: First, turn off the feed pump and the feed valve, into the lotion or inlet devices and valves, and then press and hold the "Release" button on the control panel, the piston rod driven by the pressing plate to return to retreat into the appropriate location, release the hold down the "release" button, and artificial-by-block pulling the filter plate to remove the cake at the same time clean up sticky residues in the sealing surface to prevent residues folder affect the sealing performance of the sealing surface, resulting in leakage , this one operating cycle is completed.