The CXF horizontal vacuum belt filter is a high degree of automation, new filtration equipment, and the aircraft to the filter cloth or filter media, so that the level of slurry arranged above the filter media, take full advantage of the gravity and vacuum suction of the slurry to achieve solid liquid separation. Continuous horizontal vacuum belt filter applied to the materials under a variety of concentrations, high filtration efficiency, and thus give priority to the use of many industrial sectors.

Feeding, filtration, washing off the residue cloth regeneration continuous auto-complete, high degree of automation. Multi-level advection of materials or countercurrent washing, the filtrate (mother liquor) and the washing liquid can be separated from the liquid collection. Filter is poor, high-viscosity materials, thin-layer rapid filtration. The modular design and flexible combination of adaptability. PLC control, easy remote and centralized control. Snake correction, filter cloth deviation and discounts.

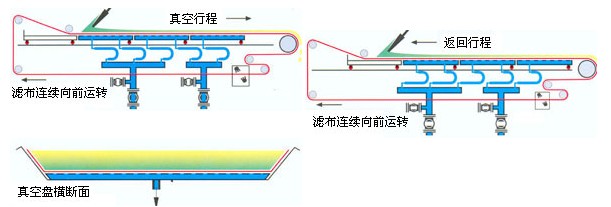

Third, the typical process map:

Fourth, the application instance table:

|

物料名称

|

液固比

|

滤饼含水率%

|

生产效率Kg/m3/h

|

物料名称

|

液固比

|

滤饼含水率%

|

生产效率Kg/m3/h

|

|

柠檬酸

|

5/1-3/1

|

15

|

25.8

|

烧碱和CUS混合液

|

4/1

|

19.6

|

416

|

|

氧化锌

|

10/1

|

51.2

|

75.9

|

ABS树脂

|

10/1

|

36-38

|

170-232

|

|

氧化锰还原酸浸矿浆

|

3.1

|

45.06

|

88.46

|

磷酸钙矿浆

|

3.5/1

|

21.5

|

345

|

|

磁铁矿

|

2.5/1-4/1

|

7.6

|

500-1000

|

溶性磷肥

|

2/1-5/1

|

7-10

|

1000-2000

|

|

硫精矿

|

4/1-2.5/1

|

11.63

|

360-800

|

硫酸污泥

|

1.5/1

|

37-40

|

665-780

|

|

铜精矿

|

4/1-2.5/1

|

12

|

400-600

|

铝钒土

|

5/1-4/1

|

26.4-29

|

1700

|

|

全尾矿

|

9/1-4/1

|

21.4

|

300-500

|

苛化泥

|

4/1

|

47-51

|

266-613

|

|

精铁矿

|

2/1-1.5/1

|

8-10

|

2000-3000

|

硫酸铝残硅

|

1.5/1

|

37

|

200

|

|

锰矿

|

2/1

|

15-17

|

800-1000

|

庆大霉素发酵液

|

1/1-2/1

|

33.1

|

78.5

|

|

氢氧化铝

|

4/1

|

15-17

|

350

|

粗氧化锌

|

4/1

|

23.5

|

233

|

|

莹石粉

|

2/1

|

11

|

800

|

含氟石灰

|

4/1-5/1

|

42-51

|

200-560

|

|

苛化泥

|

4/1

|

47-51

|

266-613

|

盐铵

|

4/1

|

18-20

|

1000-1500

|

|

五氧化 二钒

|

3/1

|

33

|

174

|

硅氟化钠

|

3/1

|

15-20

|

300-500

|

|

煤烟灰

|

10/1

|

20.7

|

4.9m3/m3/h

|

湿法水泥

|

2/1

|

16-20

|

787

|

|

金精矿

|

2/1

|

25-27

|

111

|

选煤精煤

|

4/1

|

22.4

|

218

|

|

童钨酸铵

|

2/1

|

71

|

200

|

选煤尾煤

|

6/1

|

25

|

100

|

|

偶氮在机染料

|

30/1-20/1

|

69

|

100

|

硫酸锌矿浆

|

5/1

|

45-50

|

312

|

|

4A沸石

|

80-100 g/L

|

≤43

|

164

|

种分玛瑙种子

|

200-400 g/L

|

≤20

|

684

|

|

种分玛瑙成品

|

260-600 g/L

|

≤15

|

125

|

硅渣

|

4.5

|

≤35

|

342

|

|

拜尔法氢氧化铝种子

|

400-800g/L

|

≤15

|

2000

|

脱硫石膏

|

1/1

|

<10

|

800-1000

|

|

拟薄水铝石

|

8/1

|

60

|

30-50

|

|

|

|

|

|

滤宽度

|

0.625-2.0(m)

|

2.5-3.0(m)

|

0.625m

|

1.25

|

1.6

|

2.0

|

2.5

|

3.0

|

||||||||

|

过滤长度

|

N

|

L

|

N

|

L

|

过滤面积

|

重量

|

过滤面积

|

重量

|

过滤面积

|

重量

|

过滤面积

|

重量

|

过滤面积

|

重量

|

过滤面积

|

重量

|

|

3000

|

0

|

6125

|

1

|

6150

|

1.9

|

2400

|

3.8

|

2850

|

4.8

|

3100

|

6.0

|

3400

|

7.5

|

3800

|

9.0

|

4200

|

|

4500

|

1

|

7625

|

2

|

7650

|

2.8

|

2600

|

5.6

|

3100

|

7.2

|

3400

|

9.0

|

3750

|

11.3

|

4200

|

13.5

|

4650

|

|

6000

|

2

|

9125

|

3

|

9150

|

3.8

|

2800

|

7.5

|

3350

|

9.6

|

3700

|

12.0

|

4100

|

15.0

|

4600

|

18.0

|

5100

|

|

7500

|

3

|

10625

|

4

|

10650

|

4.7

|

3000

|

9.4

|

3600

|

12.0

|

4000

|

15.0

|

4450

|

18.8

|

5000

|

22.5

|

5550

|

|

9000

|

4

|

12125

|

5

|

12150

|

5.6

|

3200

|

11.3

|

3825

|

14.4

|

4300

|

18.0

|

4800

|

22.5

|

5400

|

27.0

|

6000

|

|

10500

|

5

|

13625

|

6

|

13650

|

6.6

|

3400

|

13.1

|

4100

|

16.8

|

4600

|

21.0

|

5150

|

26.3

|

5800

|

31.5

|

6450

|

|

12000

|

6

|

15125

|

7

|

15150

|

7.5

|

3600

|

15.0

|

4350

|

19.2

|

4900

|

24.0

|

5500

|

30.0

|

6200

|

36.0

|

6900

|

|

13500

|

7

|

16625

|

8

|

16650

|

8.4

|

3800

|

16.9

|

4600

|

21.6

|

5200

|

27.0

|

5850

|

33.8

|

6600

|

40.5

|

7350

|

|

A

|

600

|

600

|

600

|

600

|

500

|

500

|

||||||||||

|

B

|

2400

|

2400

|

2400

|

2400

|

2000

|

2000

|

||||||||||

|

C

|

3000

|

3000

|

3000

|

3000

|

2000

|

2000

|

||||||||||

|

D

|

1550

|

1550

|

1650

|

1650

|

1700

|

1700

|

||||||||||

|

E

|

1100

|

1800

|

2200

|

2600

|

3150

|

3650

|

||||||||||

|

F

|

2100

|

2800

|

3200

|

4200

|

4150

|

4650

|

||||||||||

|

G

|

973.5

|

973.5

|

973.5

|

973.5

|

1028.5

|

1028.5

|

||||||||||

|

H

|

1348.5

|

1348.5

|

1348.5

|

1348.5

|

1403.5

|

1403.5

|

||||||||||

|

I

|

585

|

585

|

585

|

585

|

612

|

612

|

||||||||||

|

J

|

1104

|

1104

|

1104

|

1104

|

1163

|

1163

|

||||||||||

|

K

|

2030

|

2736

|

3136

|

3536

|

4146

|

4646

|

||||||||||

|

M

|

1300

|

1300

|

1300

|

1300

|

1300

|

1300

|

||||||||||

|

R

|

1250

|

1250

|

1250

|

1250

|

1350

|

1350

|

||||||||||

|

S

|

1400

|

2100

|

2500

|

2900

|

3450

|

3950

|

||||||||||

|

T

|

1670

|

1670

|

1770

|

1770

|

1870

|

1870

|

||||||||||

|

化

学

品

|

活性炭

|

催化剂

|

矿

物

|

氢氧化铝

|

钾盐

|

食

品

|

醋酸

|

肥

料

|

碳酸钙

|

|

氟化铝

|

染料及其中间体

|

煤的泥浆

|

|

支链淀粉衍生物

|

硫酸钙

|

||||

|

氧化铝凝胶

|

工业洗涤剂

|

铜的浓缩物

|

|

柠檬酸钙

|

硝酸钙

|

||||

|

氢氧化铝

|

氧化铁

|

黄金的沉淀物

|

|

草酸钙

|

硝酸法的泥浆

|

||||

|

磷酸铝

|

氧化铝

|

碳酸锰

|

|

硫酸钙

|

环

境 保 护 |

工业废水

|

|||

|

硫酸铝

|

锌钒白

|

氢氧化镁

|

|

谷氨酸

|

城市污水

|

||||

|

氨基酸

|

碳酸镁

|

碳酸锰

|

|

蔗糖

|

除尘污泥等

|

||||

|

钡盐

|

氢氧化镁

|

矿石沥滤残渣

|

|

柠檬酸

|

|

||||

|

硼酸盐

|

镍盐

|

磷酸盐

|

|

乳酸

|

|

|

|||

|

硼酸

|

过氧化物

|

红泥

|

|

麦芽糖

|

|

|

|||

|

溴盐

|

磷酸

|

金红石

|

|

蛋白质

|

|

|

|||

|

锌盐

|

涂料

|

银的回收物

|

|

植物油

|

|

|

|||

|

增塑剂

|

|

钛矿的分解物

|

|

|

|

|