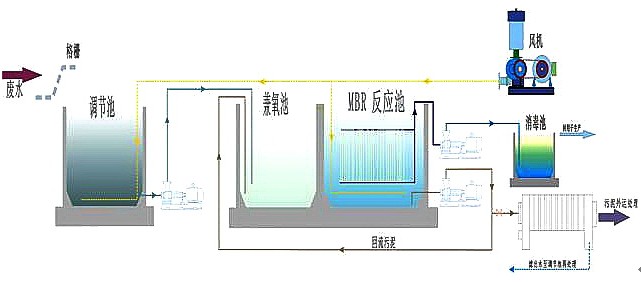

Membrane Bioreactor, referred to as the MBR treatment technology is a biotechnology and membrane technology combined with efficient biological treatment technology, membrane bioreactor is a combination of an efficient membrane separation technology and traditional sludge wastewater treatment technology. Because the role of membrane filtration, biological completely trapped in the bioreactor, to achieve a complete separation of hydraulic retention time and sludge age to maintain the higher the MLSS in the bioreactor. Nitrification ability, high pollutant removal.

The membrane bioreactor is an efficient membrane separation activated sludge which combines the new water treatment technology. The application of hollow fiber membrane replaced the activated sludge in the secondary settling tank, the solid-liquid separation, and effectively achieve the purpose of separation of the mud. Take full advantage of the efficient retention of the role of the film nitrifying bacteria, which can effectively withhold completely retained in the bioreactor, the nitration reaction to ensure a smooth, effective removal of ammonia nitrogen, to avoid the loss of sludge, and can withhold one o'clock difficult degradation of macromolecules organic matter, to prolong their residence time in the reactor, so that the maximum decomposition. The application of MBR technology, the main pollutant removal efficiency of up to: COD ≥ 93%, SS = 99.99%. Effluent suspended solids and turbidity is almost zero, the treated water quality is good and stable wastewater resources.

Second, the advantage

MBR integrated equipment is the use of membrane bioreactor (MBR) wastewater treatment and reuse of integration equipment, which has all the advantages of the membrane bioreactor: water quality, low operating cost, system impact resistance, sludge less, the degree of automation, as the integration of equipment, which has a small footprint, ease of integration. It can be as small sewage reuse equipment, but also as a central processing unit of a larger sewage treatment plants (stations), is one of the focuses of research in the field of sewage treatment has broad application prospects.

Third, the application areas

Suitable for residential quarters, office buildings, shopping malls, hotels, restaurants, offices, schools, military units, factories, and other sewage and similar industrial organic wastewater, such as textiles, beer, paper, leather, food, chemical industry, organic sewage treatment.

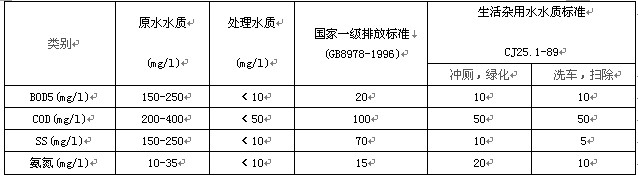

Fourth, the membrane bioreactor treatment of domestic sewage effluent

Small footprint: Due to the efficient separation of the role of the film, do not the establishment of a solid-liquid separation such as sedimentation, filtration equipment, no backwash water and suspended solids concentrations much lower than the traditional solid-liquid separation equipment, the whole system processes simple, easy to integrate The system covers an area of greatly reduced.

Savings in operating costs: the membrane bioreactor to filter out bacteria, viruses and other harmful substances, can reduce the disinfection facilities and daily dosage, management and operation more convenient.

Impact resistance, wide adaptation: to prevent the loss of a variety of microbial flora, conducive to the slow growth rate of bacteria (nitrifying bacteria) growth, macromolecular refractory organics residence time is longer, they The decomposition of the system in a variety of metabolic processes carried out smoothly.

High degree of automation: the MBR using membrane technology, greatly reducing the flow of the process, through advanced computer control technology, the device highly integrated, intelligent, and so far the highest degree of automation in the water reuse equipment.

Six MBR integration equipment superiority of the main problems:

1) the pollutant removal efficiency, the ability of anti-sludge bulking, stable and reliable water quality, effluent suspended solids;

2) membrane bioreactor reactor SRT STR and hydraulic retention time of HRT were controlled, and therefore its design and operation is greatly simplified;

3) membrane mechanical interception of avoiding the loss of micro-organisms, can maintain a high sludge concentration in the bioreactor, which can increase the volume load, reducing the sludge load, has a strong impact resistance;

4) SRT is very long, the bioreactor, but also played the role of the sludge nitrification pool, thereby significantly reducing sludge production, low excess sludge production, low cost of sludge treatment;

5) make the SRT due to the diversion effect of the membrane to extend, and create conducive to slow the proliferation of microorganisms. Such as nitrifying bacteria growth environment, can improve the nitrification capacity of the system, at the same time help to improve the processing efficiency of refractory organic macromolecules and to promote their complete decomposition;

6) the MBR aeration tank activated sludge will not be with the water loss during operation, the activated sludge will enter the changes in the concentration of organic matter changes, and achieve a dynamic equilibrium, which makes the system water stable and resistant to the impact of the characteristics of the load;

7) hydraulic cycle led to the uniform mixing of the sewage, thus activated sludge with good dispersion, greatly improving the specific surface area of activated sludge. Activated sludge in the MBR system is highly decentralized is another reason to improve the water treatment effect. This is a common biochemical method water treatment technology form larger zoogloea to be compared;

8) membrane bioreactor easy integration, easy to implement automatic control, easy operation and management;

9) the MBR process is omitted, the secondary settling tank and disinfection tank, reduce floor space;