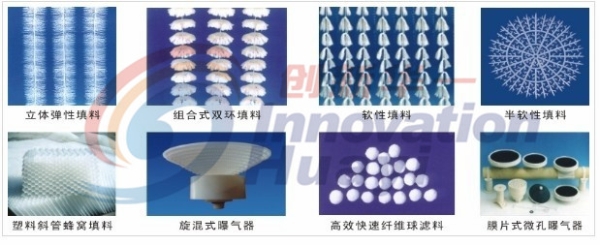

The packing screening wear several polyolefin and polyamide, heat resistance, anti-aging high-quality varieties, mixed hydrophilic, adsorption, thermal oxidative additives, special brushed yarn-hair process wire article interspersed with solid in the corrosion-resistant, high strength of the center of the rope, due to the excellent selection and formula, hard and soft moderate, so that the filament was a three-dimensional uniform arrangement of the radiation state, made of a suspended three-dimensional elastic filler monomer, filler in the effective area of stereoscopic full range of uniform stretch covered with gas, water, biofilm fully mixed infiltration contact exchange, the biofilms not only evenly implantation in each filament to maintain the activity and the gap variability, but also during operation increasing specific surface area, but also a good metabolism, this feature of the phenomenon of domestic filler incomparable.

The filler and the rigid class cellular packing, pore variability is not blocked; compared with the soft class packing material long life, non-stick connected group; compared with the semi-soft stuffing, a large surface area, rapid biofilm low cost. Therefore, the filler can be confirmed following a variety of rigid class packing, soft packing and semi-soft stuffing novel fourth-generation energy-efficient packing.

Second, the modular bicyclic filler

The advantages of modular packing set of soft and semi-soft stuffing, to overcome the drawbacks of both, as compared with the ideal product in the biochemical processing of the sewage. It is a plastic ring for the skeleton, load the wire of polyvinyl alcohol, polyvinyl alcohol fiber wire fastening the plastic ring on the tow sewage evenly distributed, and prone to film for film, adaptability and sewage concentrated liquid, widely used in sewage and wastewater treatment.

Third, soft filler

Soft filler since the successful trial, because of its large surface area, high utilization, do not plug the gap variable, to adapt to a wide range of low cost, freight and other advantages, in recent years has been widely used for dyeing silk, wool, food, pharmaceutical, petrochemical, paper, linen, hospital, cyanide wastewater treatment in order to make it play a greater product features and economic benefits, in recent years under the guidance and assistance of the relevant scientific research units, the soft filler innovation in the form a variety of reasonable structure, the better to overcome the actual surface area of the original appears not easily broken, the center rope, the middle of the fiber bundles agglomerate ills, which the majority of users welcome.

Four, semi-soft stuffing

Semi-soft filler with high thermal performance, resistance, water distribution, gas distribution performance, easy long film, but also cut bubble effect. It used materials are polypropylene, polyethylene. For sewage, wastewater treatment works, supporting the contact oxidation tower, oxidation tank and other equipment. Cell diameter is generally in Ø120, Ø150, the center rope plastic rope and fiber rope specifications according to the equipment design departments and users.

5, oblique tube honeycomb filler

Inclined tube is mainly used for the precipitation and Desanding role. Decade the most widely adopted and become a treatment plant in the water supply and drainage. It was adapted to a wide range of treatment effect, and small footprint. Adapt intake Desanding, general industrial and domestic sewage to sedimentation, sewage sedimentation, grease and Owari concentrated treatment, apply to new construction, but also applies to the transformation of the existing old pool, it has achieved good economic .

Main features:

Wet weeks old, the hydraulic radius is small

2 laminar flow conditions, particle deposition turbulence interference;

Oblique tube length of 1 meters, payload of 3-5 tons / cubic meter design. VO control in the range of 2.5-3.0 mm / sec, the best water quality;

The glass honeycomb inclined tube, the tube length in the 2.0-3.0 m in the 50-100 kg / cubic meter of silt content, high turbidity in the safe operation of the processing at the water intake.

5 Sedimentation, 3-5 times the processing capacity for rectangular sedimentation tanks, which is accelerated clarifier clarifiers and pulse 2 times.

Six spin mixed aeration tube

Spin-mixed aeration is a new type of aeration device is improved on the basis of the spiral aerators, diffuser type aerator, Jinshan aerator of a new type of aeration device, the product is resistant to corrosion , oxygen utilization to engage in, the main features difficult to congestion and easy to install. Multislice spiral cut in the form of spin-mixing aerators oxygenating aeration when air into the mixed flow aerator, air first through the two spiral cutting system, after cutting into the underlying multi-layer zigzag cloth gas head multi-layer cutting, cut into micro-bubbles to make bubbles, thereby greatly enhancing the utilization of oxygen, with a uniform gas distribution and high oxygenation efficiency.

Seven, efficient and fast fiber ball filter

Filter characteristics: was under the dense flexible, compressible, the porosity of the sewage interception capability; work when the filter pore memorial, in line with the pore size distribution of the ideal filter layer; proportion slightly larger than the water, easy to backwash material quality have strong wear resistance and resistance to chemical attack.

Diaphragm microporous aeration tube

Diaphragm microporous aeration aeration device developed in the 1980s, change the device aeration bubble diameter, gas-liquid area, bubble spread evenly, does not produce holes to plug, strong corrosion resistance, the Shanghai Tongji University of Environmental Engineering and the North China Municipal Engineering Design Institute for water and sewage oxygenation tests and many users use that to good effect. Especially suitable for urban sewage and large factories, the new expansion and transformation of the old aeration tank, aeration tank intermittent operation.