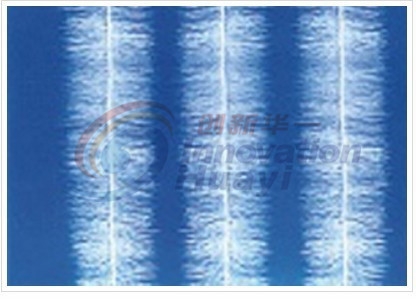

The packing screening wear several polyolefin and polyamide, heat resistance, anti-aging high-quality varieties, mixed hydrophilic, adsorption, thermal oxidative additives, special brushed yarn-hair process wire article interspersed with solid in the corrosion-resistant, high strength of the center of the rope, due to the excellent selection and formula, hard and soft moderate, so that the filament was a three-dimensional uniform arrangement of the radiation state, made of a suspended three-dimensional elastic filler monomer, filler in the effective area of stereoscopic full range of uniform stretch covered with gas, water, biofilm fully mixed infiltration contact exchange, the biofilms not only evenly implantation in each filament to maintain the activity and the gap variability, but also during operation increasing specific surface area, but also a good metabolism, this feature of the phenomenon of domestic filler incomparable.

The filler and the rigid class cellular packing, pore variability is not blocked; compared with the soft class packing material long life, non-stick connected group; compared with the semi-soft stuffing, a large surface area, rapid biofilm low cost. Therefore, the filler can be confirmed following a variety of rigid class packing, soft packing and semi-soft stuffing novel fourth-generation energy-efficient packing.

Biological contact oxidation is attached to the carrier (commonly known as fillers) on the biofilm-based purification of a highly efficient organic wastewater treatment process. Has been widely used in textile printing and dyeing, woolen knitting, beer, food, petrochemical and fertilizer waste water, medical care and living sewage processing, and access to the obvious environmental benefits, social and economic benefits. In recent years, with the water supply required quantity increase, coupled with the organic pollution of rivers, lakes, water and other surface water to varying degrees by a large area, using the contact oxidation process for processing. Over the years, the process of energy efficient, small footprint and resistance to shock loading, run the easy management, and other unique advantages widely used in the design department, welcomed by the users and favor.

Biofilm Carriers is a core part of contact oxidation process, which directly affects the treatment effect of oxygenation performance, infrastructure investment, operation period and the cost. The factory production launch of the three-dimensional elastic filler and hybrid three-dimensional elastic filler I plant a variety of conditions and the large number of experiments and long production run, the results show that the ideal Carriers. Due to the unique structure of the filler and the fine material process selection, it has a long life, good oxygenation performance, low power, start biofilm stripping updated easily, resistant to high shock loading, the treatment effect is significant, running management is simple, is not blocked, that does not bear groups and the advantages of low prices. The packing in the different application of process water conditions, adjustable yarn thickness density and different forms of assembly, is fully applicable to a variety of wastewater anaerobic, anoxic and aerobic treatment process. The filler is home and abroad, and its structure, properties of international advanced level.

The filler screened several corrosion-resistant polyolefin and polyamide, heat resistance, anti-aging high-quality varieties, mixed hydrophilic, adsorption, thermal oxidative additives, special brushed, yarn-hair process wire article interspersed with solid in the corrosion-resistant, high strength of the center of the rope, due to the excellent selection and formula, hard and soft moderate, so that the filament was a three-dimensional uniform arrangement of the radiation state, made of a suspended three-dimensional elastic filler monomer, filler in the effective area of stereoscopic full range of uniform stretch covered with gas, water, biofilm fully mixed infiltration contact exchange, the biofilms not only evenly implantation in each filament to maintain the activity and the gap variability, but also during operation increasing specific surface area, but also a good metabolism, this feature of the phenomenon of domestic filler incomparable.

The filler and the rigid class cellular packing, pore variability is not blocked; compared with the soft class packing material long life, non-stick connected group; compared with the semi-soft stuffing, a large surface area, rapid biofilm low cost. Therefore, the filler can be confirmed is the fourth generation of energy efficient, following a variety of rigid class filler, a soft class of fillers and soft fillers novel packing.