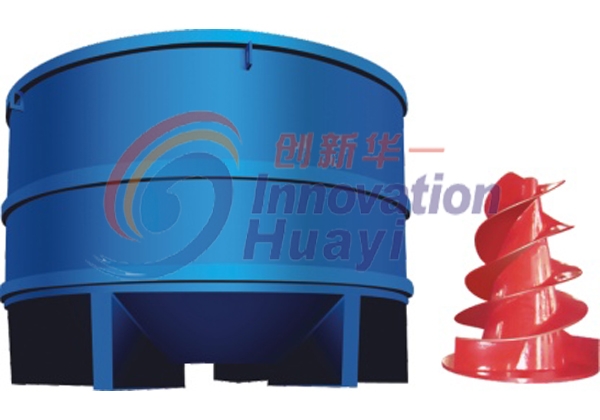

The high concentration Hydrapulper is one of the indispensable equipment in the waste paper deinking pulp, its role in addition to pieces of paper solution outside the pulp, as well as the pulp fibers generated intense friction in the rotor rotation, so that the printing ink off, and the role of chemicals from the fiber surface so as to achieve the purpose of the recycled pulp. The rotor of the machine for long helical blade rotor, has a powerful role in the shredding, the working concentration of 15% -18%, the operation can produce strong top-down flow of plasma and the rotation of the plasma flow along the tank. The pulp of good quality and uniformity. This machine has a novel design, reasonable, high concentrations of shredding, energy saving, etc., is fine shredding equipment.

Second, the specifications and parameters:

|

型号

|

公称容积(M³)

|

生产能力(T/D)

|

碎浆浓度(%)

|

电机功率(KW)

|

|

|

ZGS-3

|

3

|

9-12

|

14±2%

|

55

|

|

|

ZGS-5

|

5

|

13-18

|

14±2%

|

75

|

|

|

ZGS-8

|

8

|

20-30

|

14±2%

|

110

|

|

|

ZGS-10

|

10

|

30-45

|

14±2%

|

160

|

|

|

ZGS-15

|

15

|

45-60

|

14±2%

|

220

|

|

|

ZGS-20

|

20

|

60-80

|

14±2%

|

310

|

|

|

ZGS-25

|

25

|

90-120

|

16±2%

|

400

|

|

A. Patent structure of the high concentration pulper rotor pulping at high concentrations (about 3 percentage points higher than the traditional high-concentration pulper); for waste paper deinking pulp processing can greatly reduce the energy consumption of slurry heating and chemicals consumption; ease stronger; to promote the ink particles quickly stripped from the fiber and dispersion; and almost no cut off the role of the individual fibers; the destructive effects of small impurities advantages.

Two. No need to patent the structure of the discharge dilution device enables high concentration slurry in the the pulper tube dilution directly discharge, greatly reducing the discharge time of high concentration slurry, reducing the dynamic configuration of equipment to save power consumption, especially for post- The process of high concentration slurry.

Fourth, the equipment installation

(1) sets out of the box to check equipment.

The arrangement according to the basic diagrams and equipment and technology foundation endurance level to the actual situation to determine the basic design, the basis of the elevation process layout and operating requirements.

(3) the equipment base to the centerline of the centerline of the tank and impeller pulper benchmark positioning, basic axis and the design axis spacing tolerance is ± 10mm base surface reserved for secondary grouting thickness of 20 ~~ 25mm.

Watering equipment before installation of equipment by the solidification of the health based.

Equipment lifting (hoisting rope to be tied to the tank, not hanging in the shaft) on the basis of its datum point and install the base line distance and standard, respectively, from the tolerance of ± 2mm and ± 1mm.

Check installation size is correct, for the first time grouting.

By the solidification of the health, locking bolt, re-check the spindle vertical degree of tolerance <0.1mm / m, tank level of tolerance is ± 2mm / m, correct, and then the second grouting.

8 according to process requirements, the assembly pipeline, operating platform, feeding equipment, railings, etc..

9 do the installation and construction of the original records, including: facility location, the first, second grouting, installation accuracy and so on.

Note: 5M3 above models, the tank in the floor.

Fifth, use and maintenance

(A) The test machine:

Inspection equipment fastening screws are loose, drive V-belt is appropriate, the drive wheel rotation is flexible.

(2) to start the motor to see the impeller direction of rotation is required.

3 in the slot in vivo injection, start the motor continuous operation of not less than one hour.

Should pay attention to the direction of flow 4. Commissioning to meet the requirements, inspection equipment at any time with or without vibration, noise, electrical load to check for compliance, the spindle bearing temperature not exceeding 60 º C.

(5) the device is working properly you can put into use.

(B) the engine off:

1, before starting to prepare:

(1) The waste paper selection by hand, hanging to the floor.

(2) hot water be in hot water compartment preheated to the desired temperature, plus waste paper, broken solution temperature reaches 60 º C is appropriate.

(3) the deinking agents with the measurement of chemicals according to the process provisions.

(4) Check the tank body residues, the rotor binding, V-belt no obstructions, and electrical facilities are in good condition, the bearing is to raise oil lubrication.

(5) to open the hot water valve first heating the water and chemicals, hot water, joined by the metering barrel accurate, deinking agent to join the slot in vivo by the artificial weighing.

2, boot and shutdown:

Ready to do a good job, you can boot into the waste paper raw materials in the absence of exceptional circumstances, the feed should be completed in the shortest possible time, so as not to waste paper uneven gravel extraction and de-inking reaction, this time weighing pulp pH value of PH12 about -13 (PH value of less than should to join NaCO3 or NaOH to adjust), the full dissociation of the waste paper, ink and chemical complete response and falling down from the fiber surface and began to put the pulp, first open the dilution water valve, and then start to put the pulp put slurry pump, close the dilution water valve, slurry put after shutdown and the slurry in the bottom of water pipe cleaning, removal of the rotor winding material (rope or thread). The shredding process ends.

Sixth, Care and Maintenance

Often to inspect the equipment, pay special attention to the rotating part and the bracket bolts the availability of loose leaves with or without significant wear and tear, flanges and valves for any leakage, leakage of plasma, bearing with or without overheating.

2, the main axis of the main lubrication points two bearings, bearing lubrication cycle for five days, is generally lubricant on the 2nd of calcium or sodium based grease, lubrication method for hand refueling.

3, suggest that about a year, the first overhaul

Seven, after-sales service

Free guide to installation and commissioning.