Chain scraping the residue (oil) machine equipment for wastewater treatment in flotation unit, Our company has developed products for a variety of flotation device used in conjunction, it is specifically designed to remove grease in industrial and urban sewage, plastic bar as well as suspended solids. Particularly applicable to scrape the flocculation treatment process to produce scum. Application of the principles of the chain of transmission, supporting the installation according to the civil user requirements. In accordance with the treatment of sewage water and the Pharmacy plus, you can adjust the scraping residue speed, to complete the task of scraping the residue in order to achieve minimum power consumption.

Chain scraping the residue (oil) machine with local conditions, slag handling the amount of control a flexible, stable operation. The convenient operation, easy maintenance, long life characteristics.

2 works

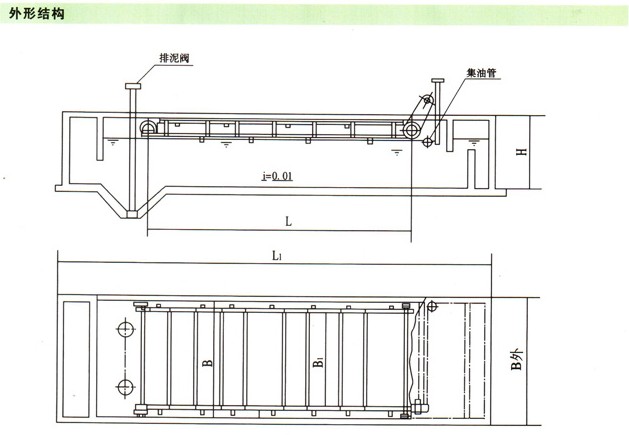

Chain scraping the residue (oil) machine is continuously floating on the water, suspended solids removal, scraping the residue (oil) machine along the entire surface movement, and suspended solids from the inlet of the flotation tank pushing the export side. Scraping residue (oil) machine scraper is fixed at both ends of the chain, scraping residue (oil) machine is driven by the sprocket gear driven by the stepless speed regulation. Scraping residue (oil) machine along the entire width of the slot move the contaminants blown slagging slot.

3, the installation of the machine

3.1 driving shaft and driven shaft in the same parallel line, install the drive shaft, then install the driven shaft.

3.2 sprocket must be in the same line when installing the first chain on the driving shaft sprocket, secure the drive shaft, according to the length of the chain to determine the installation of the driven shaft (driven shaft is best to adjust chain tightness degrees). The chain order must be consistent, fixed scraper nylon links must be bi-directional alignment.

After installation, the 330 two-axle and chain mounting bracket combination of pieces.

3.4 combined with the installation after scraper installation.

3.5 according to the scene to install the stepless speed regulation and steel chain connected.

3.6 all combined with properly installed, check each part with pieces of tightness, a parallel situation, the power drive test run.

3.7 variable speed device must be powered car for speed, chain scraping residue (oil) machine per minute line speed 5.16 25.8m/min (adjusted depending on site conditions).

4 machine care and maintenance

4.1 The aircraft should be noted that the care and maintenance, timely fuel, such as failure should be immediately removed.

4.2 The aircraft run-in period of one month to the machine gearbox oil should let go of the chain scraping residue (oil), open the flush, oil change.

4.3 in the case of normal operation, the variable speed device dedicated stepless synthetic oil, the first oil change time is 500 hours, after the oil once every six months, users need an alternate synthetic speed Machinery Factory guarantees supply.

4.4 Steel chain of weekly oil on the chain gun dropping 20 # machine oil, moderate.

Chain scraping residue (oil) machine supporting details

Chain scraping the residue (oil) machine is the basic configuration is as follows:

1, the scraper is made of 304 stainless steel plate, thickness 1.5mm + nitrile rubber sheet, the thickness of 8mm

2, sprockets, chains, high-strength nylon; caterpillar Q235

3, the chain adjusting screw is stainless steel,

4, scraping residue Drive Shaft: Carbon steel corrosion

5, stepless speed regulation: According to the flotation machine the size of matching the domestic well-known variable speed device, running more than ten years no problem.

Note: The above device configuration for reference only, the user according to the actual situation of choice, can also be a special custom.